Where can I hit someone to disable them

The drill can drill precise and smooth holes up to 16.5 seconds. It includes all accessories necessary to meet your needs.

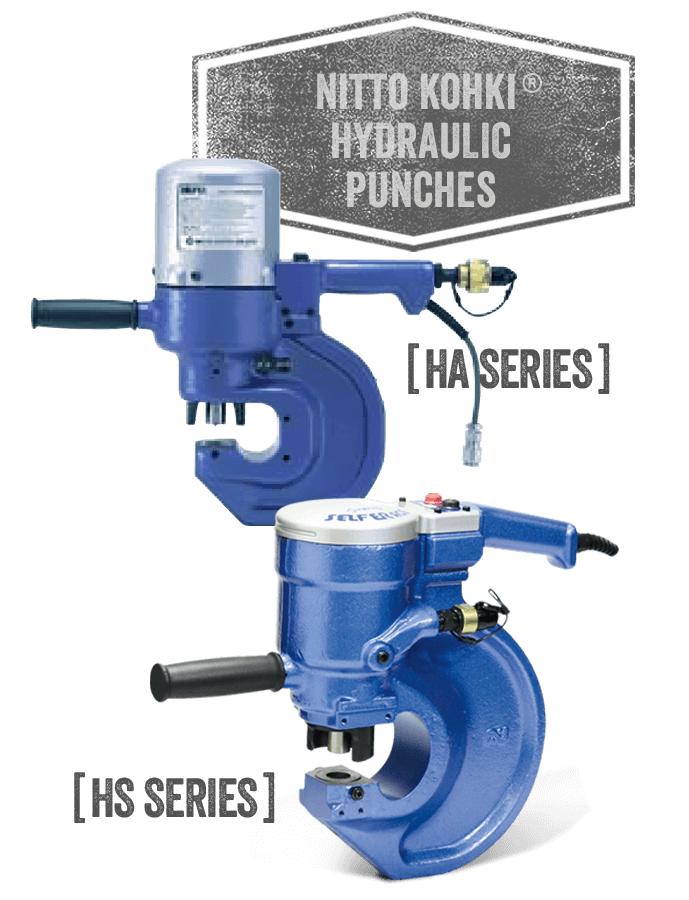

These single-acting hydraulic punches are used extensively in the electric industry, construction, and other outdoor fieldwork. It allows for a maximum punching thickness up to 16mm, maximum punching width of 24mm, maximum throat depth of 110mm, and maximum punching distance of 24mm.